SINTRA MIX-IND systems are constituted by perforated ducts made exactly like SPIROJET ducts, but designed with Patented Technologies, capable of energy performances and comfort levels well above those attained by the traditional systems of air distribution.

These patented technologies include: -

PULSERS®: Air Pulsion is a unique air distribution technology. Mixing the input air with the ambient air, it creates a pressure filed along the ducts axis which sets the entire environment air mass in controlled motion. A PULSION system is designed, manufactured and assembled with bespoke perforated ducts called PULSERS. PULSERS are high induction ducts characterized by two sizes of perforation.

TWIN™: Splitting the PULSERS® functionalities. Instead of having just one pulser® with a big diameter (ie:1700mm), there are two or more parallel pulsers® (ie:1200mm) which give more flexibility in terms of variable airflow and subsequent energy savings.

- Two primary pulsers® (also called functional pulser®): Work on a constant and minimum airflow and monitor the strict temperature homogeneity in the space (Δt +/-1°)

- Secondary pulser®: Works as a power discharge. Its main functionality is to introduce the excess air flow (secondary airflow) without specific direction but without disrupting the functional pulser.

VARIBOOST®: This technology boosts the airflow power when required (ie: following loading bays opening, or newly introduced materials). Special dampers located in the plenums can intercept the secondary airflow in order to boost the primary Pulsers®.

VARIAMIX®: Calculated perforated system which tolerates a variation of the air speed coming out from the holes between 70% and 100%, without significant loss of performance

VARITRAPâ: Patented mechanical calibration system for the manual regulation of the residual air speed at ground level.

HYGROCOOLINGâ: Patented system for the humidification and adiabatic cooling which uses the pulser’s micro-turbulent flux to vaporize the atomized water drops.

Click here for link to Sintra 'Pulsion' Video

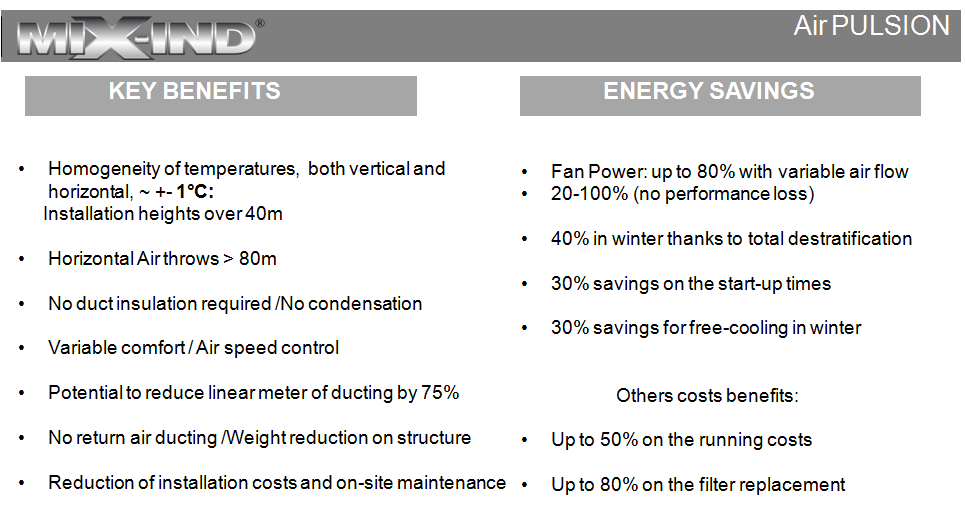

Compared to traditional Air Distributions Systems, MIX-IND systems offer the following significant advantages: -

- Homogeneity of both vertical and horizontal temperatures (with +/- 1

oC, regardless of the building height);

oC, regardless of the building height);- Maximum comfort with optimal control of the residual speeds in the occupied zone;

- Total de-stratification, especially for high buildings, even higher than 40m;

- No return air ducts, therefore less pressure loss for the fans, less maintenance costs, less encumbrances and reduced cost of the ducts;

- Total recovery of all endogenous heat produced in the local (engines, lighting, etc.);

- Applicable both to high-rise and low-rise buildings, without any loss of performance;

- Easy to bypass any potential major obstacles on the site;

- Possibility to introduce air at low temperature directly into the room without discomfort or condensation problems;

- Ability to perform long air throws, so less ducts to install, less weight on the structures, less encumbrances in the room and a lower total cost of ducts;

- Possibility to significantly reduce the overall cost of the plant, using the free service of AIDED DESIGN with can eventually allow an optimization of the plant’s air flow, especially for medium and large volume buildings.

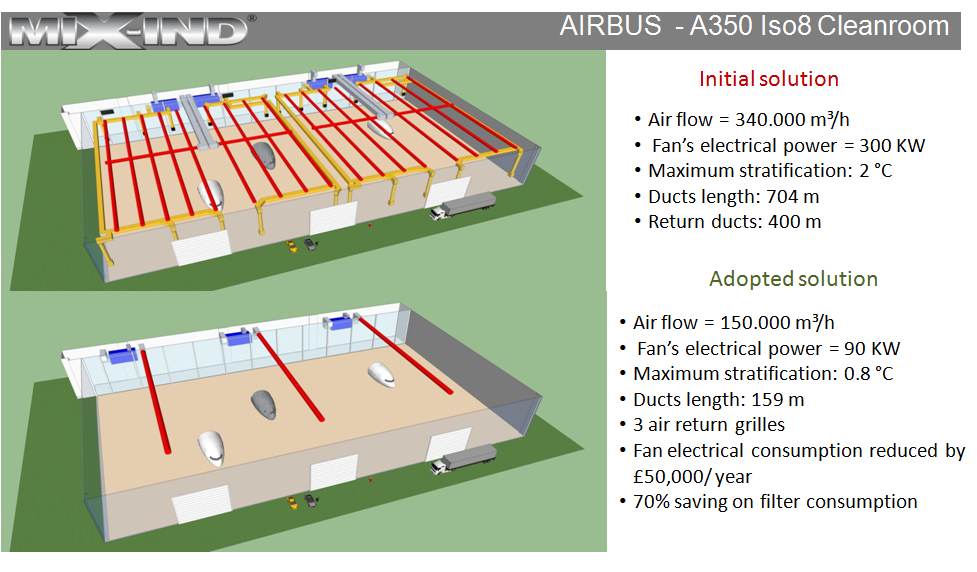

Case Study - AIRBUS Bouguenais

Key Beneifts / Energy Savings

Click here for further information on Sintra Mix-Ind Technology.

For more information or to arrange a product presentation / technical selection, please contact Jason Keating – 014511244 or contact us at info@coolair.ie